Automation.

Quartus engineers have a proven track record in providing high precision and high-speed automation systems using state of the art technology and algorithms. Quartus works with our customers to design, build & test bespoke automation systems when no commercial off the shelf options are available.

CAPABILITIES

Industrial Automation

- Automation design using COTS PLCs and embedded systems

- PLC and ladder logic programming

- Wiring harnesses and electrical box installation

- System build and testing

Complete System Development

- Requirements definition, systems engineering, instrument development, prototyping

- Cross-discipline engineering teams leveraging mechanical, electrical, & software expertise

Electronic Control Systems

- Domain expertise in control theory and developing application specific control algorithms

- High speed implementation of control algorithms in firmware, FPGA, or on COTS PLC platforms

- Complete electronics control system development including integration of custom PCBs and COTS components, programming, assembly, and test

CASE STUDY

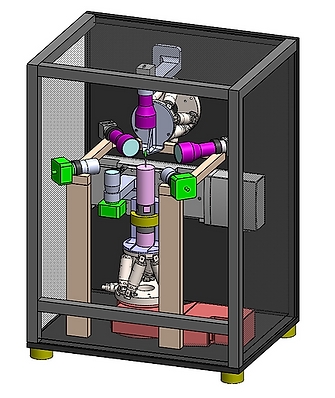

Custom Industrial Automation

Quartus engineers designed, analyzed, built, and fully tested a spaceborne dual axis gimbal mechanism for high-throughput optical inter-satellite links. The effort focused on lowering manufacturing costs, minimizing complexity, and reducing risk for high volume manufacturing (targeted +1,000 per year) for a coarse pointing assembly and launch lock device for satellite constellation communication. The coarse pointing assembly was capable of providing precision line-of-sight articulation over a near-hemispherical field of regard, all while using mainly commercial off-the-shelf components.

- Automation design using COTS PLCs and embedded systems

- PLC and ladder logic programming

- Wiring harnesses and electrical box installation

- System build and testing

- Machine vision

- Visual servoing

- Real-time processing

- High speed placement

- High precision alignment

- Harsh environments